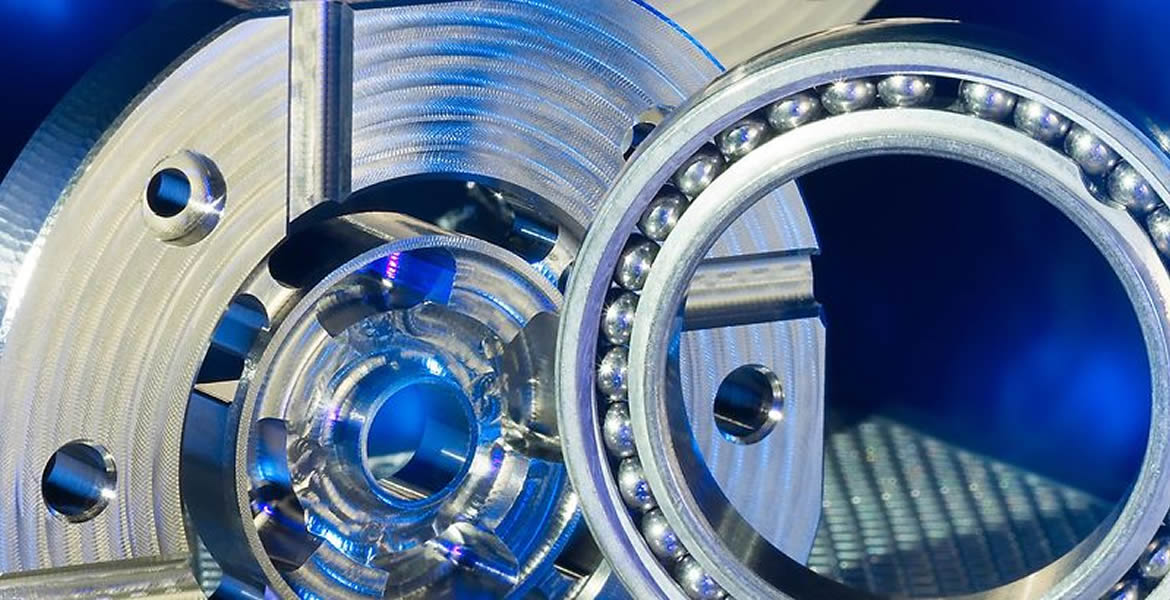

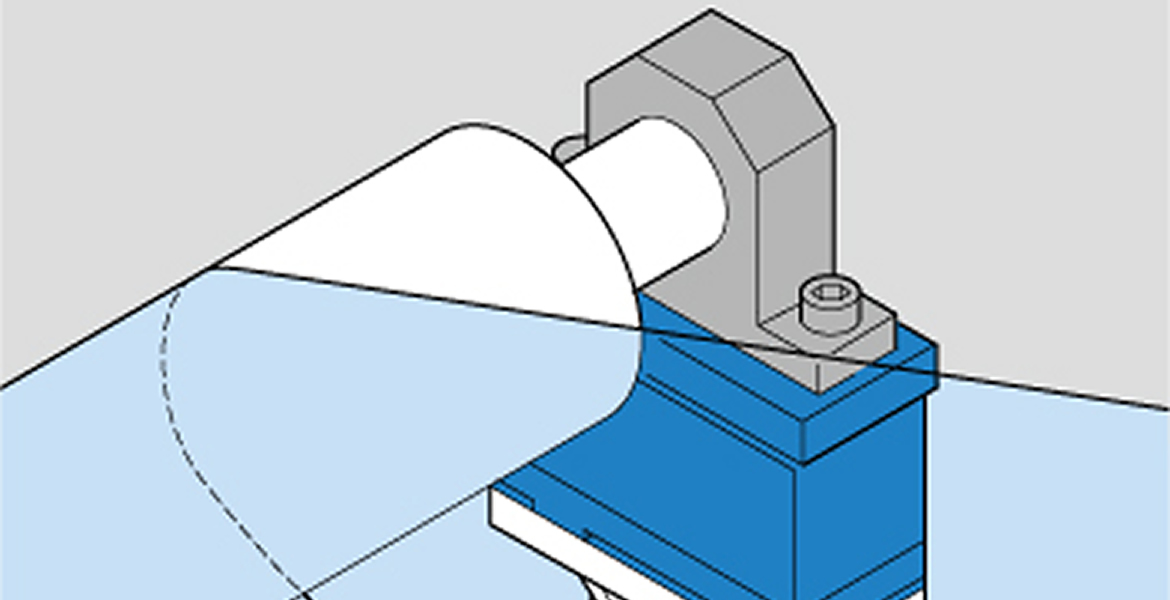

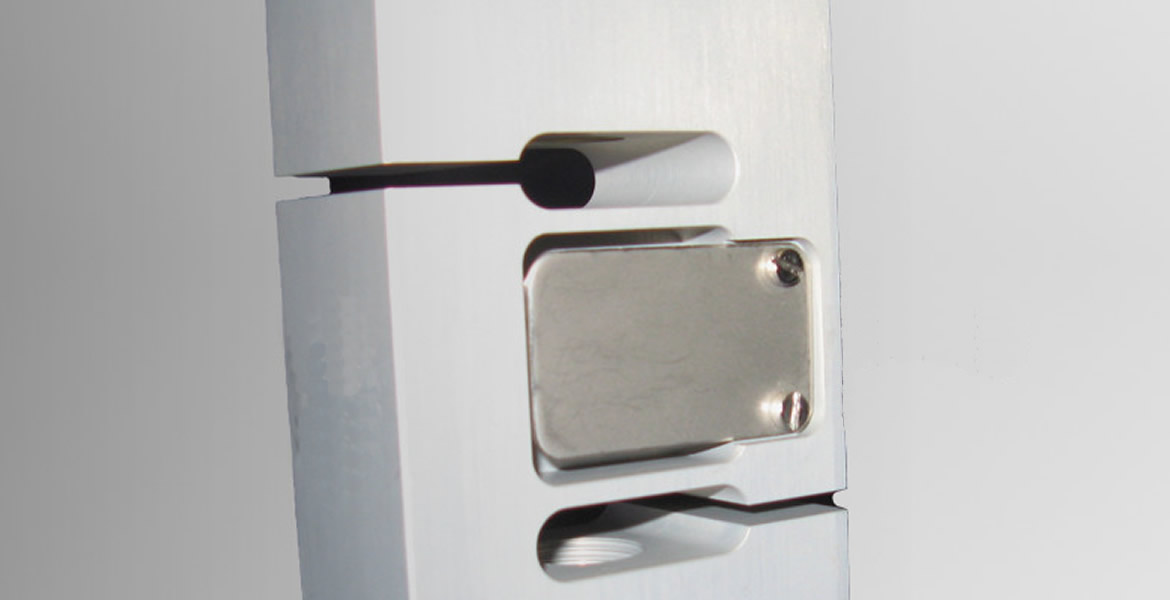

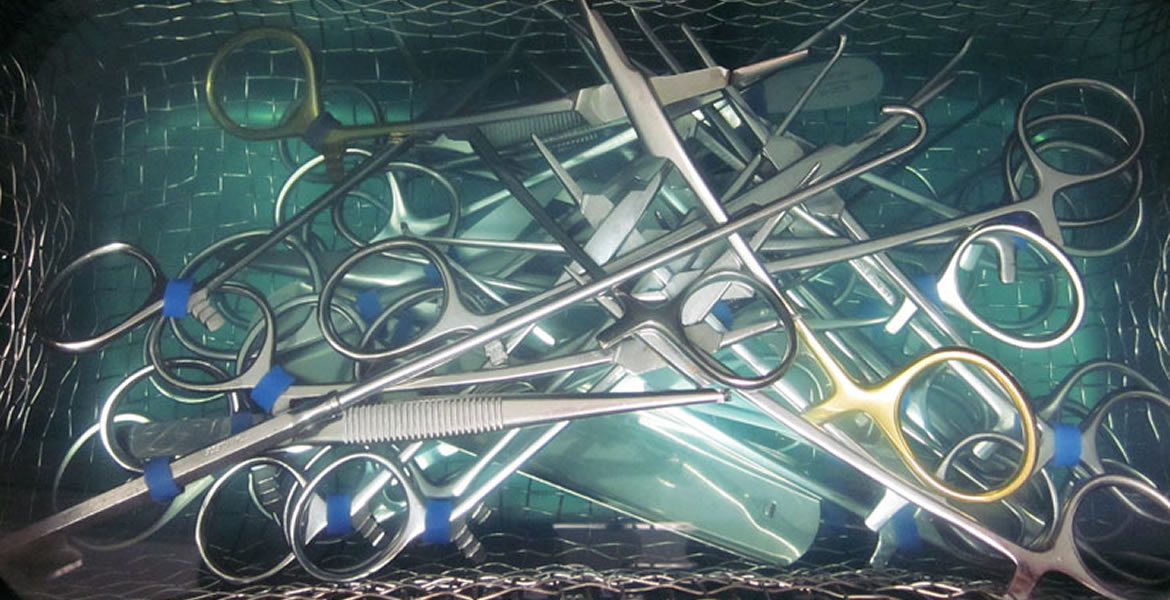

Ultrasonic cleaning equipment applied in the process of industrial production belongs to the realm of industrial precision cleaning. Ultrasonic cleaning technology is widely used in many fields such as food, textile, paper, printing industry, petroleum processing industry, transportation, electric power, metal processing industry, machinery, automobile manufacturing, instrumentation & electronics, household appliances, medical, etc.